What is PLM for?

Working from a Single Source of Truth (SSOT), digitized platform for every product decision you make requires unifying both your data and processes effectively. A holistically connected product lifecycle management system coupled with the inherent digital enablement in well-designed PLM software will uncover opportunities for improved products, processes, and marketability. These result in:

- Lightning Speed to Market – Innovation cycles shorten to help capitalize on consumer trends.

- Team Collaboration – Product developers, regulatory compliance specialists, packaging engineers and quality managers in far-flung regions or countries work together for change, from an unchanging version of the truth.

- Product Pipeline Efficiencies – From idea to development, to development to distribution and beyond, find new energy in your pipeline using PLM integration to power productivity and profitability.

- Idea Scoring and Data Modeling – Run an idea through a mirrored system before even one resource is committed and create a knowledge database using PLM integration, a rich source of ideas for improving processes, inventing the right products for your next category-defining launch.

- Control Proprietary Data – AI/ML built into a PLM platform fosters knowledge-building opportunities at every click. In a digitized marketplace within an Industry 4.0 ecosystem, most companies’ value is now centered in their ability to manage their proprietary data and share that knowledge internally to spur new innovation.

- Ironclad Compliance – Trace every step in quality management across the entire supply chain and assure your products are compliant in all markets in which you sell them, thanks to a centralized regulatory database for real world transparency, now and in the future.

Examples of PLM Software Use in Real Companies

-

Case Study #1

Global Confectionary giant Lindt upgraded its Trace One Devex PLM platform to embrace innovation and maintain compliance

-

Case Study #2

Barilla builds efficiency at every stage of product development

-

Case Study #3

Global dairy company uses Trace One Analytics to save time and increase efficiency

History of PLM in Process Manufacturing

In the past, PLM management teams used office software, file folders, and clipboards in the lab and on the factory floor to manage their products and portfolios. The first digitized PLM systems were designed to manage launch activities and included simple workflow tables and charts in Excel, segmented by internal processes like purchasing, materials management, and product compliance. The software required extensive customization, even within the same industry, and was limited to a single, or at most, 2-3 functional silos of activity in each organization. In 1995, Selerant (now Trace One) introduced the first PLM system specific to process manufacturers in 1995. Today, it supports 9,000 brand owners with callable solutions that support the entire product manufacturing lifecycle.

Second generation PLM

Project management software sometimes centralized these PLM activities but was rarely integrated with the systems that managed processes, such as request for proposal (RFP) and procurement or engineering change systems. By 2000, the pressures of a globalized marketplace and the speed of commercialization birthed new PLM software, and included capabilities for manufacturing processes along with product commercialization. Pricing, distribution, and integrated feedback from suppliers enabled continuous improvement initiatives for manufacturers and for customer-facing teams.

PLM systems now

While these mid-2000s tools enabled simplified workflows and processes, they were often lacking in analytics and reporting. PLM information was centralized; most could access it when needed; however, users could not readily identify process improvement opportunities and uncover weaknesses in the supply chain or react quickly to changes during launch.

The maintenance and retirement phases for existing products also became increasingly important as global legislation for recycling and other disposal rules proliferated.

Most PLM software did not have a robust mechanism for dealing with new regulations in real time—or provide tools to capture changing customer or competitor signals and act on them.

In contrast, modern PLM software for process manufacturers and CPG retailers uses application programming interfaces (APIs) to form connective tissue into the heart of a company’s enterprise resource planning (ERP) and other legacy systems. Modern PLM software support end-to-end product development process, from ideation, formulation, supplier collaboration, specification management with embedded regulatory compliance and quality management. Modern PLM extends to suppliers and customers, ensuring visibility and trust transcends organizational boundaries.

Cloud-based PLM enhances responses to suppliers, customer signals and internal innovators. It makes the modern product ideation process marketable, at the speed of trends. Cloud-based PLM systems offer scalability and offer instant accessibility without the need for excessive IT infrastructure.

What is PLM? Stages of Product Lifecycle Management

From creating products through every data point on a single product’s journey, product lifecycle management tracks a product throughout its entire lifetime.

Product concept and ingredients sourcing

Customer needs, competitor analysis or gaps in the market spur the product concept design phase, where a product’s requirements are defined. Raw materials, suppliers, and eventual production, launch and maintenance are often included in modern product design, as are regulatory and repurposing recycling needs.

Development

Once a product idea is validated, teams begin product development, ideally using a SSOT for master bill of materials (BOMS) and master data specifications and management to birth each new product. Process manufacturers, in particular, require formula-based development that is centralized, with a recipe repository with:

- Integrated tools and processes for transparency

- Traceable data

- Efficient activities and workflows

- End-to-end innovation, based on increased visibility and the ability to act on new information

During this phase, R&D and marketing work with launch messaging; suppliers are contacted for ingredients; regulatory, quality and packaging teams finalize their requirements; and production and launch can begin.

Reformulation follows after a recipe-based product has been on the market. The timeframe varies, but process manufacturers and CPG manufacturers often retire a formulation or recipe in its original format and/or repackage and relaunch it.

Production and launch

Getting a go-to-market product to scale may be one of the biggest challenges facing process manufacturers and CPG retailers. They execute with effective supply chain management, BOM management, and regulatory and plant documentations and certifications.

Services and support

After launch, manufacturers offer services and support to consumers and customers, including contact center and website feedback as well as managing recalls or ingredients compliance changes.

How it Works: Use Cases for PLM Software

Find out how real-world companies use PLM software to enable quicker innovation, compliance by design, save resources, and manage risk better.

Food and Beverage PLM and Compliance Stories

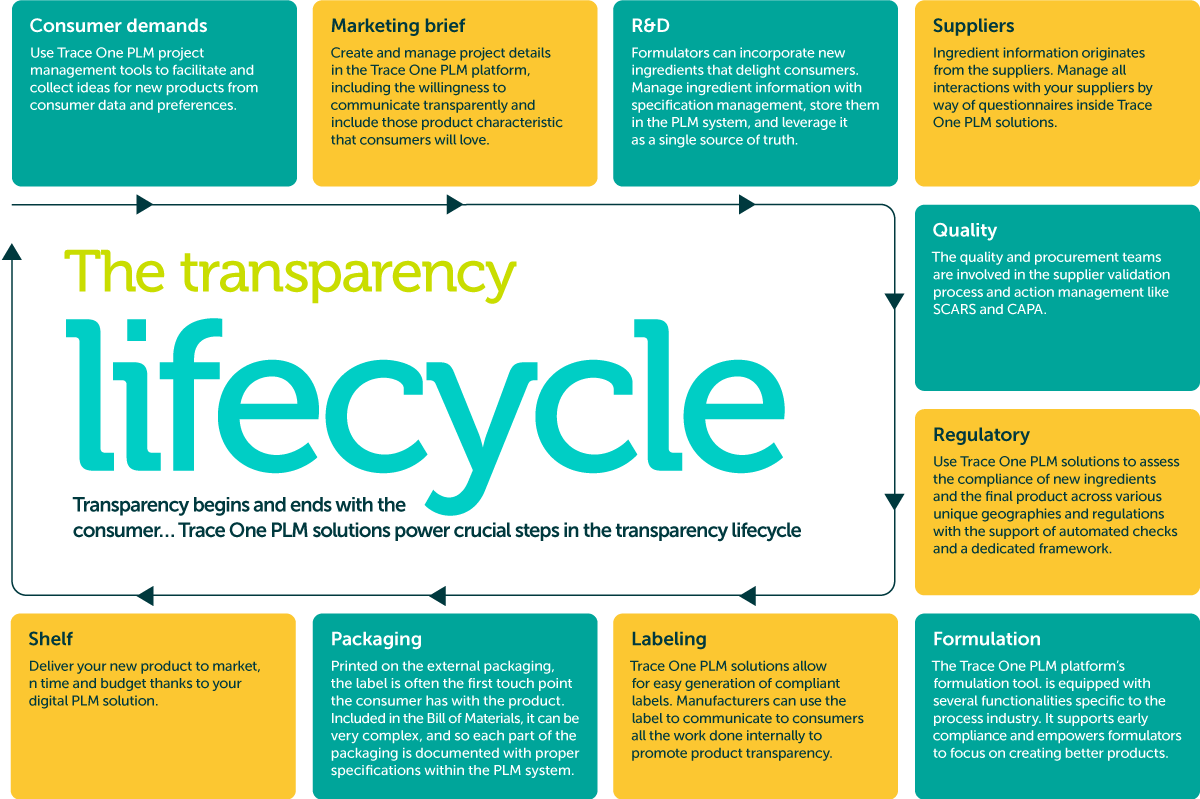

Trace One Devex PLM for the food and beverage industry, Trace One Regulatory Compliance, and Trace One Sustainability provide powerful and comprehensive solutions for the entire product lifecycle.

Can you perfect governance using a PLM? How about change everything in your New Product Development and Introduction (NPDI) workflows for more consistent recipe simulation and nutritional value calculations?

Trust and transparency in the food supply chain

To improve relationships between manufacturers and consumers, a number of food manufacturing giants like Nestle and Cargill use the enhanced transparency and traceability in PLM software.

PLM helps beauty, skincare and cosmetic product formulators develop faster and deliver on-trend products to customers

Why is PLM so important for cosmetics manufacturers? Cosmetics companies must manage new product development and introduction processes in one place. PLM software helps them gain greater control, transparency, and oversight over beauty product development to get products to market faster.

When digitizing product lifecycle management workflows, the company needed to leverage its existing formula systems consistently yet find new ways to uncover the value in recombining ingredients to launch innovative products to market faster.

A global leader in the industry, this customer’s journey to a solid project portfolio management solution with a single global data repository and financial framework now supports all locations, accounts, and currencies—worldwide.

Specialty chemicals manufacturers and suppliers

The specialty chemicals industry requires specific tools to equip their teams and optimize product development. Trace One customers have shortened time to market with boosts to efficiency in their PLM processes and built compliance and quality in from end to end.

An $18B automotive coatings leader needed to ensure color matching for collision repair techs. They used Trace One Devex PLM to centralize web-based color matching tools designed to connect to every aspect of their business.

PLM helps CPG retailers innovate products faster – true stories of customers’ PLM struggles and achievements

CPG brands improve process, ensure compliance, enhance supplier relationships, and access deeper analytical insights with a powerful ecosystem of interconnected solutions to manage analytics, suppliers, tendering, and packaging for an integrated digital solution to help meet rising consumer expectations and secure customer trust.

Connection and simplicity

- Day-to-day support

- Accelerated go-to-market

- Informed strategy and decision-making

- Rapid adoption

- Streamlined integration

- Security and configurability

The AI advantage: Accelerating time to market through artificial intelligence

Manufacturers are always looking for ways to speed time to market while mitigating risk. Integrated product lifecycle management (PLM) solutions have revolutionized the NPDI process, and the emergence of advanced AI tools represents new possibilities. They’re making an impact across all kinds of industries and disciplines, but their potential for accelerating time to market is especially powerful in process manufacturing.

The shift from customized to pre-configured software solutions

While the private brand industry is a mature and thriving global market, there is still a lot of room for growth with respect to how private brand owners implement and achieve the most effective product lifecycle management (PLM) tools for their supply chains.

PLM and ERP – What’s the difference?

Enterprise Resource Planning (ERP) systems include different business software and applications for finance, human resources, distribution, manufacturing, and the supply chain. ERP supports both administrative and operational business processes and manages assets across a company.

In contrast, PLM software supports a strategy of managing products through their lifecycle across multiple operational and administrative tasks. The goal of PLM is to provide a digital thread for a product within the entire ecosystem of operations. Both ERP and PLM will share a “common process and data model” (Gartner) for many functions, PLM software specifically supports product management by storing and synchronizing product iterations for finished products in the ERP system.

Why would a company integrate ERP and PLM systems? The answer is: to master product data and expedite product launch.

When a company connects their ERP to their PLM system, they are connecting complex workflows within a single source of the truth (SSOT). This “digital thread” pulls through actionable data from products and PLM processes into the centralized data and processes of the entire company within its ERP.

For more details, click here: PLM and ERP at Trace One.

Looking Forward: The Future of PLM

Trace One PLM solutions enable advanced emerging use cases for product lifecycle data. As the world becomes more interconnected and data-driven, new capabilities are being realized to aid companies at every stage of product lifecycle management.

“Industry 4.0” refers to the “Fourth Industrial Revolution” and describes companies with full digitization, connected data nodes across their product lifecycle, all the way from the supplier through launch and to the consumer beyond. When a PLM system includes business partners and entire product ecosystems using the internet of things (IOT) to link to supply, operations, manufacturing, companies are better equipped to make decisions that advance their goals. Transparency, data intelligence, instant reporting and continuous improvement processes are all enabled within an Industry 4.0. company. Digitized product lifecycle management is the linchpin for growth and profitable change for these companies.

Artificial intelligence and machine learning (AI/ML) allow data to be mined for intelligence, powering all facets of the product lifecycle. Process innovations uncovered through AI/ML reporting may allow for improved operations, and responsiveness to market signals, and to customer or consumer feedback. AI/ML can help manufacturers understand how consumers use their products and provide additional marketplace agility.

Am I ready for Product Lifecycle Management (PLM) software?

Here are the six main areas to review as you consider your move.

- A less-than-well-defined product lifecycle PLM software leverages a well-defined product lifecycle (PL). If you have significant gaps in understanding your PL, you need PLM tools more than ever. If you’re ideating, developing and launching products, you have a form of PLM, it just may need to be improved by best practices from a high-performing PLM system. What is PLM for but to help institutionalize your already solid product management processes and fix what needs fixing?

- Growing product complexity Process manufacturers, food systems organizations, specialty chemical companies and personal care and cosmetics companies all require multiple versions, revisions and stringent feedback and approval workflows during product lifecycle management. If this is you, PLM will manage these better than the status quo, which is probably not tenable in the long term.

- Need for speedy and single source of truth (SSOT) collaboration: Your teams shouldn’t have to work with disparate product information housed in fragmented systems and then be forced to regroup and figure out where they are. If they’re to align behind a solid product lifecycle strategy, they need a centralized platform for data and communications.

- Keep data manageable and valuable: Inept version control, spotty or half-paper-, half-computer-based document management and being unable to mine the value of your data are clues you need PLM tools. Are you starting over from scratch from a data perspective every product cycle? You’re probably ready to take your data to the next level.

- Difficulty tracking regulations and compliance: A regulatory workflow that includes a real-time library plugged into your PLM software can help you maintain accurate records, and keep certifications up to date, for suppliers and for your manufacturing facilities.

- Scalability, Expansion and Growth: PLM software early in any expansion plan will help scale processes and systems to support your strategy. PLM systems allow you to track all new product development needs in one place. Growth in your portfolio will mean additional complexity in formulation requirements, as will acquisitions and mergers. If these types of changes are on your company roadmap, a PLM system will be crucial for their enablement.

If you decide it’s time to move on PLM, you might want to ensure you have or have plans to obtain executive sponsorship, change management, and effective resource allocation to support your PLM project. These three focus areas will allow you to begin sourcing software, and plan team involvement for final implementation. A dedicated workflow for change management allows for a smoother transition, as well, and minimizes disruptions. If you have gaps in one or more of these areas, the software partner you choose will help you assess your readiness and plan for all of the phases of PLM software implementation, based on their experience helping others in your industry.

PLM Frequently Asked Questions (FAQ)

What is PLM?

From creating products through every data point on a single product’s journey, product lifecycle management (PLM) tracks a product throughout its entire lifetime. It includes these five phases: concept and design; development; production and launch; services and support; and retirement.

What is a PLM system?

A PLM system helps teams manage the product lifecycle management process. It ensures compliance and facilitates end-to-end innovation throughout product development. PLM tools and processes also boost the visibility, harmonization, validation, and traceability of data and activity at each stage of the product lifecycle.

What is the difference between a PLM system and an ERP system?

Enterprise Resource Planning (ERP) systems integrate various business functions such as finance, HR, and supply chain management, enhancing administrative and operational processes across a company. Product Lifecycle Management (PLM) software, on the other hand, focuses on managing products throughout their lifecycle, aiming to create digital continuity across all operational and administrative tasks.

What does a PLM system typically cost?

Costs vary widely depending on the size of a company, implementation scope, number of users, customizations and licensing, and ongoing maintenance costs. Most PLM system users migrating from legacy systems or instituting a new PLM system will look to recoup costs from retiring legacy software and by realizing a return on their investment (ROI) by using their PLM system to accelerate time to market and speed innovation cycles, thereby driving greater profits.

How do I know I am ready for a PLM system?

Formula-based product developers and manufacturers who are experiencing growth, increasing product complexity and having difficulty managing changing compliance needs can look into PLM systems to solve these issues. Ineffective collaboration, documentation and stagnant innovation cycles and/or misaligned supply chain processes can also be clues that you need a PLM system.

Let’s Get in Touch

Connect with us to learn how Trace One Devex PLM can serve your organization’s unique needs.